Over the past few weeks we’ve looked at thread checkers to identify nuts and bolts, handy flexible hose clamp pliers and battery desulfators . This week’s cool tool, generically known as heat-shrink self-solder butt-splice connectors, make wiring jobs quick and seemingly safe and reliable. The big deal is that you won’t need to plug in a soldering iron or fire up a torch — these make the connection and seal the joint using a hot air gun (like a paint stripping tool) or even a pocket lighter.

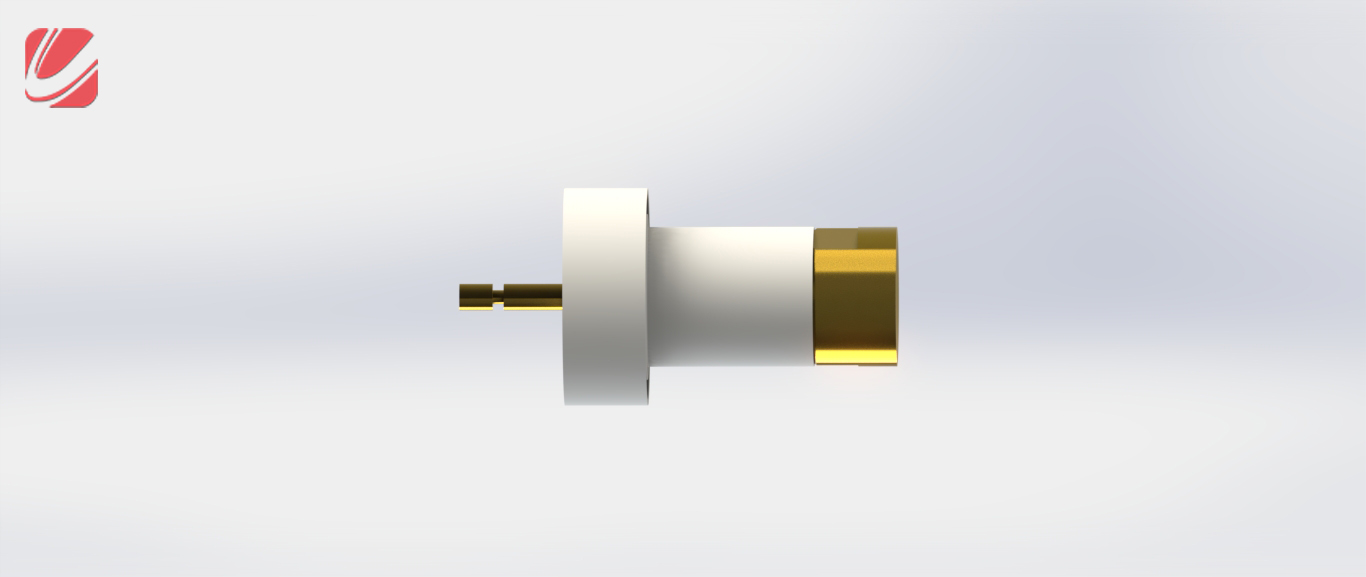

This recommendation comes from Rory, who says he recently used these to wire up some lights on his GX 470. According to him: Survey Gyroscope

I hate wiring. I hate diagnosing electrical faults, I hate routing wires, making butt connections, and I hate soldering. So I decided to give these a try.

First, I’ll say that there are differing opinions on what is the “correct way” to connect wires. I typically default to soldering and heat shrinking because that makes the most sense to me logically — it’s a strong connection that’s resistant to water intrusion and corrosion. Sometimes, working in tight spaces, I’ll resort to butt or blade connectors with some heat shrink over them. Soldering on a bench is one thing, but making a good solder while lying under a car is another.

For the same reasons that a good solder job makes sense, these little things seem like a good idea, at least in theory. There’s a solder joint in the middle and a heat shrink sheath that’s sealed on either end with some hot, sticky glue. Obviously, I had some concerns about how well the solder would penetrate, but after watching the video below, I decided to give it a shot.

Big Clive concludes that a traditional solder and heat shrink technique creates a better solder joint, and I have no doubt that it does. But my own testing resulted in a pretty consistent connection that will likely outlast a butt connector, while providing good resistance to water. I did add another layer of heat shrink over the whole deal because, why not?

Cable Lug Joint Have you tried these connectors, or do you have another connector you swear by? Do you know of a weird or unique but must-have tool you think every wrencher should have? Do you want to see us put a type of tool to the test and see how it performs? Shoot me an email or drop it down in the comments!