Hyundai’s ‘Uni Wheel’ system gives more room for different car designs

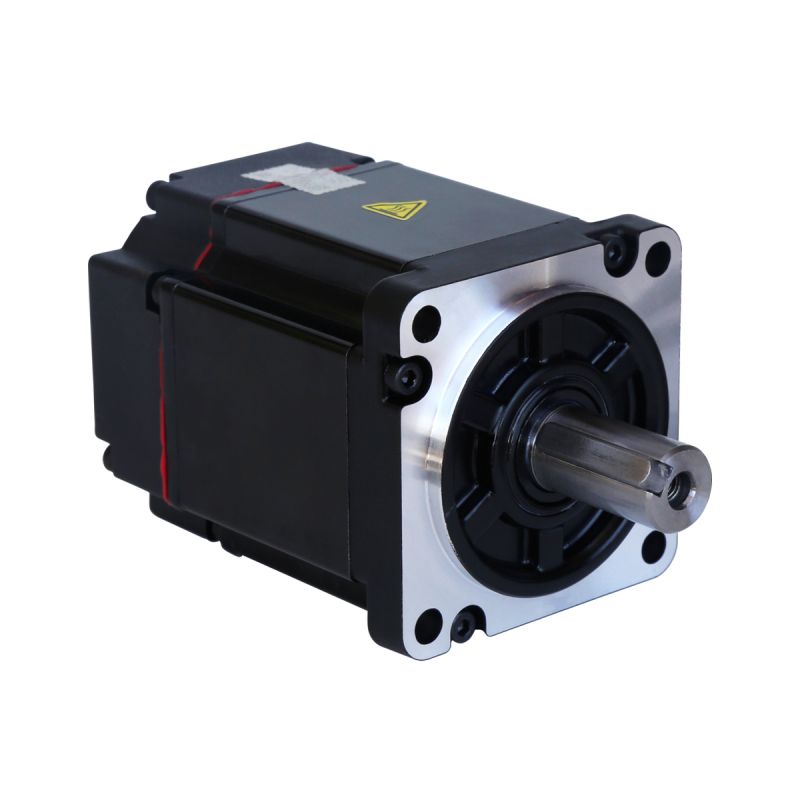

Hyundai’s “Uni-wheel” system integrates the constant velocity joints, drive shaft and car decelerator into the wheel, connecting small motors to each wheel. (Hyundai Motor Group) 13nch Amr Dc Motor

120kg Load Electric Driving Motor Wheel Hyundai Motor Group on Tuesday unveiled a more compact, integrated wheel system that frees up more room for futuristic car designs. Called “Uni Wheel,” short for Universal Wheel Drive System, the system integrates the constant velocity joints – a device that links the vehicle’s transmission to its wheels – and other parts such as the drive shaft and car decelerator into a wheel. The system, the first of its kind, also connects smaller motors to each wheel, instead of placing them between the wheels. “(In the case of Hyundai Motor Group’s electric cars,) there is a large space between the left and right wheels of the EV platform E-GMP, however, the electric powertrain is installed there (having little space for other installation or unique layout design),” said Park Jong-sul, a senior research fellow at the institute of advanced technology development of Hyundai Motor Group, during a press conference in Seoul. Hyundai said the extra space can be used as trunk space, wider passenger seats, or room for EV batteries, allowing for more creative seating options, especially for futuristic mobility such as self-driving cars and highly customized cars like robot-based delivery robots. According to Kim Ki-seok, another researcher at the institute, the wheel system also can be installed in almost all wheels ranging from 4-inch wheels for wheelchairs and bicycles to 25-inch vans, regardless of engine type. Powered by Uni-wheel’s separate motor system, one-seater mobility or cars will be able to climb stairs smoothly as if it is going up an escalator, Kim noted, adding that completing the technology development is one of the company’s key projects. “It has been 2 1/2 years since the Uni Wheel was born. Currently, we’ve finished the phase 2 development process,” said Park. “Our next year’s goal is to make a seal and a cover for the wheel system and advance the technology so that it can soon be installed in cars including purpose built vehicles.” Park added that the new wheel drive system will first be used in the rear wheels of premium EV lineups due to its high cost. “The next step will be incorporating rotational steering within the Uni Wheel. We plan to work with Hyundai Mobis, who developed the ‘Crab Walking’ wheel, to develop a module that combines in-wheel motors, rotational steering and electronic braking,” Park noted. Hyundai Mobis, an auto parts manufacturing unit under Hyundai Motor Group, unveiled in April the “e-Corner System,” which allows the car to move sideways like a crab by rotating its wheels 90 degrees -- a feature especially helpful for parallel parking. Uni Wheel’s unique technology was either registered or granted a total of eight patents worldwide including in Korea, the US and Europe. The carmaker boasted that the system does not make the sun gear -- an external gear attached to the central axis of a planetary gear -- rotate when the wheel moves, delivering the motor power to the wheel in a stable manner. It can extend the electric car range on a rough road or in case of driving at high speed. By Byun Hye-jin (hyejin2@heraldcorp.com)